69 Users Online

Revision: 20161206_014233 | All Revisions

I have received five of these AEG M4/M16 high cap magazines out of the Evike's Box of Awesomeness (470K Fan Edition). By now, I have moved onto mid-caps, but it is still interesting to know how a high-cap magazine works. Therefore, I am reviewing it in this article and providing disassembly instructions.

The magazine is metal, winding, high-capacity, and fits the M4/M16 airsoft rifle. The finish is matte black (see photo below), which reflects very little light. The package says it can hold 300 rounds of BB's.

The top of the magazine is the typical feeder, the sliding door to load BB's, and a switch to unload all BB's at once (see photo below). The switch actuates easily with fingernail. The loading hole allows you to load BB's without any special tools. But a small funnel can help you load BB's quicker. Like other high capacity magazines, it rattles a little bit without any BB's and rattles a lot when filled with BB's.

At the bottom of the magazine is the winding wheel (see photo below). It's pretty typical of any airsoft high-cap magazine, because you wind the wheel toward the front of the magazine.

We found that on a full wound, the Asia Electronic Guns M4 M16 High Cap Magazine can feed 12 rounds before it needs to be wound again. Not the greatest number for a high cap mag as you can shoot all twelve rounds within a second in full-auto mode. So be sure to keep winding the magazine as you play.

A hex screw on the bottom of the magazine, close to the winding wheel, allows you to take it apart. You'll need a 2.5mm hex wrench, a little bigger than the 2mm hex screws I seen on other M4 magazines. However, the thread size is the same on the 2.5mm and the 2mm hex screws.

Once you unscrew the hex screw, the plastic insert is still attached to the metal shell via two small tabs on each side of the magazine. Push both tabs in slightly and you can pull out the plastic insert from the top. The photo below shows the plastic insert next to the metal shell. The winding wheel has a hex nut on it. If you drill a hole in the metal shell, you can use a hex wrench to wind it.

Two screws, on the right side of the magazine (see photo below) keeps the plastic insert together. After unscrew the two screw, you can pull the shell apart. Be careful with the BB unloading mechanism as it is under spring tension.

I disassembled another magazine out of the five. It has five screws (see photo below). It seems the assembly is inconsistent.

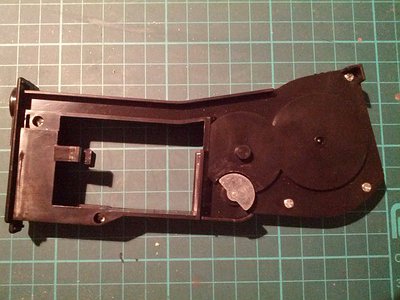

The following photo shows the inside of a high-cap magazine with the winding wheel.

One of the magazine had a loose winding wheel. As I rotate it, it stopped clicking. In addition, it unwound after I let go. I took it apart and found that the winding wheel was snapped on, no other fasteners. The snapped on winding wheel was loose. As I turned it, it moved out of position from the anti-reversal pin (the clicker).

To prevent the winding wheel from moving out again, I used a standard #14 O-ring (used on the piston head) to keep the winding wheel in pace. The photo above shows the #14 O-ring placement.